Polyether Ether Ketone (PEEK) is a high-performance thermoplastic polymer known for its exceptional mechanical, thermal, and chemical properties. PEEK plays a crucial role in the medical industry due to its biocompatibility, strength, and durability. This blog explores the various applications of PEEK in the medical field, highlighting its importance and benefits. For those interested in the latest pricing information, visit our Polyether Ether Ketone Price page.

Understanding Polyether Ether Ketone (PEEK)

PEEK is a semicrystalline thermoplastic polymer that boasts a unique combination of properties:

High Mechanical Strength: PEEK exhibits excellent tensile strength, stiffness, and dimensional stability.

Thermal Stability: It remains stable at high temperatures, with a continuous operating temperature of up to 260°C.

Chemical Resistance: PEEK resists various chemicals, including acids, bases, and solvents.

Biocompatibility: It is highly compatible with human tissue, making it suitable for medical implants and devices.

These attributes make PEEK a preferred material in various high-performance applications, including those in the medical industry.

Applications of PEEK in the Medical Industry

Orthopaedic Implants

One of the most significant applications of PEEK in the medical industry is in orthopaedic implants. PEEK’s strength and biocompatibility make it ideal for spinal implants, joint replacements, and fracture fixation devices. Its radiolucent properties ensure that PEEK implants do not interfere with X-ray imaging, allowing for clear visualization of surrounding tissues and bone growth. Additionally, PEEK’s ability to be sterilized using standard methods makes it a practical choice for implants that must be free from contaminants.

Dental Implants and Prosthetics

In dentistry, PEEK is used to manufacture dental implants and prosthetics. Its strength and resistance to wear and tear make it suitable for applications such as crowns, bridges, and denture bases. PEEK’s biocompatibility ensures it integrates well with the surrounding oral tissues, reducing the risk of adverse reactions. Moreover, its lightweight nature and aesthetic appeal make it a preferred choice for dental prosthetics requiring functionality and appearance.

Surgical Instruments

PEEK is increasingly used to produce surgical instruments and tools due to its durability and resistance to sterilization processes. Surgical tools made from PEEK can withstand the harsh conditions of autoclaving and other sterilization methods without losing their integrity. The material’s mechanical properties ensure that instruments maintain their precision and performance over time, contributing to better surgical outcomes and reducing the risk of instrument failure.

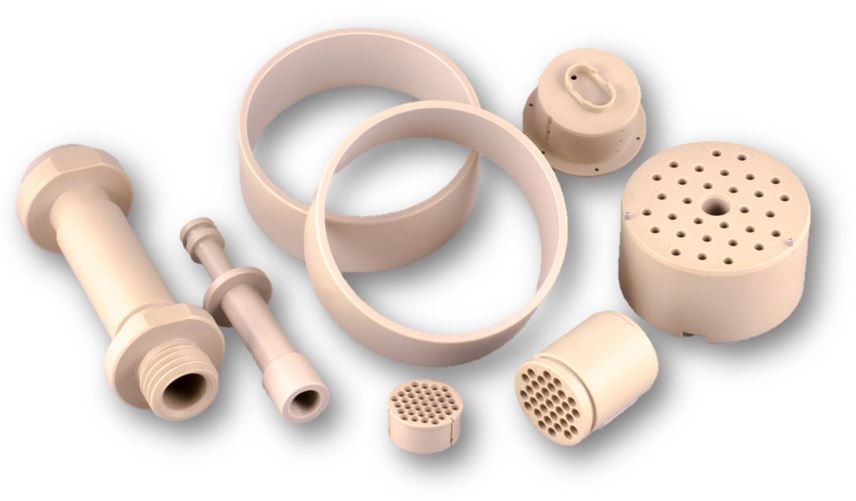

Medical Device Components

The versatility of PEEK extends to its use in various components of medical devices. It is used to manufacture parts such as housings, connectors, and functional components of devices like endoscopes, infusion pumps, and surgical robots. PEEK’s thermal stability and chemical resistance ensure that these components perform reliably under various operating conditions and exposure to various substances.

Implantable Cardiovascular Devices

PEEK is also utilized in implantable cardiovascular devices, such as stents and vascular grafts. The material’s strength and flexibility allow for the creation of devices that can withstand the dynamic forces of blood flow while maintaining their structural integrity. PEEK’s biocompatibility ensures that it does not provoke an adverse immune response, making it suitable for long-term implantation in the cardiovascular system.

Advantages of Using PEEK in Medical Applications

Biocompatibility: PEEK’s compatibility with human tissue minimizes the risk of inflammation and rejection, making it a reliable choice for implants and devices that remain in the body for extended periods.

Durability: The material’s mechanical strength and resistance to wear ensure that medical devices and implants maintain their functionality and structural integrity over time.

Thermal and Chemical Resistance: PEEK’s ability to withstand high temperatures and chemical exposure makes it suitable for use in various sterilization processes and harsh medical environments.

Radiolucency: PEEK does not interfere with imaging techniques, allowing for clear visualization of implants and surrounding tissues during diagnostic procedures.

Future Trends and Developments

The role of PEEK in the medical industry is expected to grow as advancements in material science and technology continue to evolve. Research is focused on enhancing the properties of PEEK and exploring new applications, including:

Enhanced Composite Materials: Combining PEEK with other materials creates composites with improved properties for specialized medical applications.

3D Printing: Using PEEK in additive manufacturing to produce customized implants and devices with precise specifications.

Bioactive PEEK: Developing PEEK with bioactive properties that promote better integration with bone and tissue.

For those interested in sourcing PEEK materials, keeping track of pricing and availability is essential. Visit our Polyether Ether Ketone Price page to stay informed about the latest market trends and pricing information.