In recent years, Swiss screw machining has become an essential technology in various industries, but its impact on the automotive industry is especially significant. This advanced machining process is revolutionizing the way automotive parts are produced, leading to increased efficiency, precision, and cost savings. The automotive industry, which thrives on innovation and performance, has found Swiss screw machining to be an invaluable tool. Let’s dive into how Swiss screw machining and swiss machine shop usa are transforming the automotive industry and why it’s such a game-changer.

What is Swiss Screw Machining?

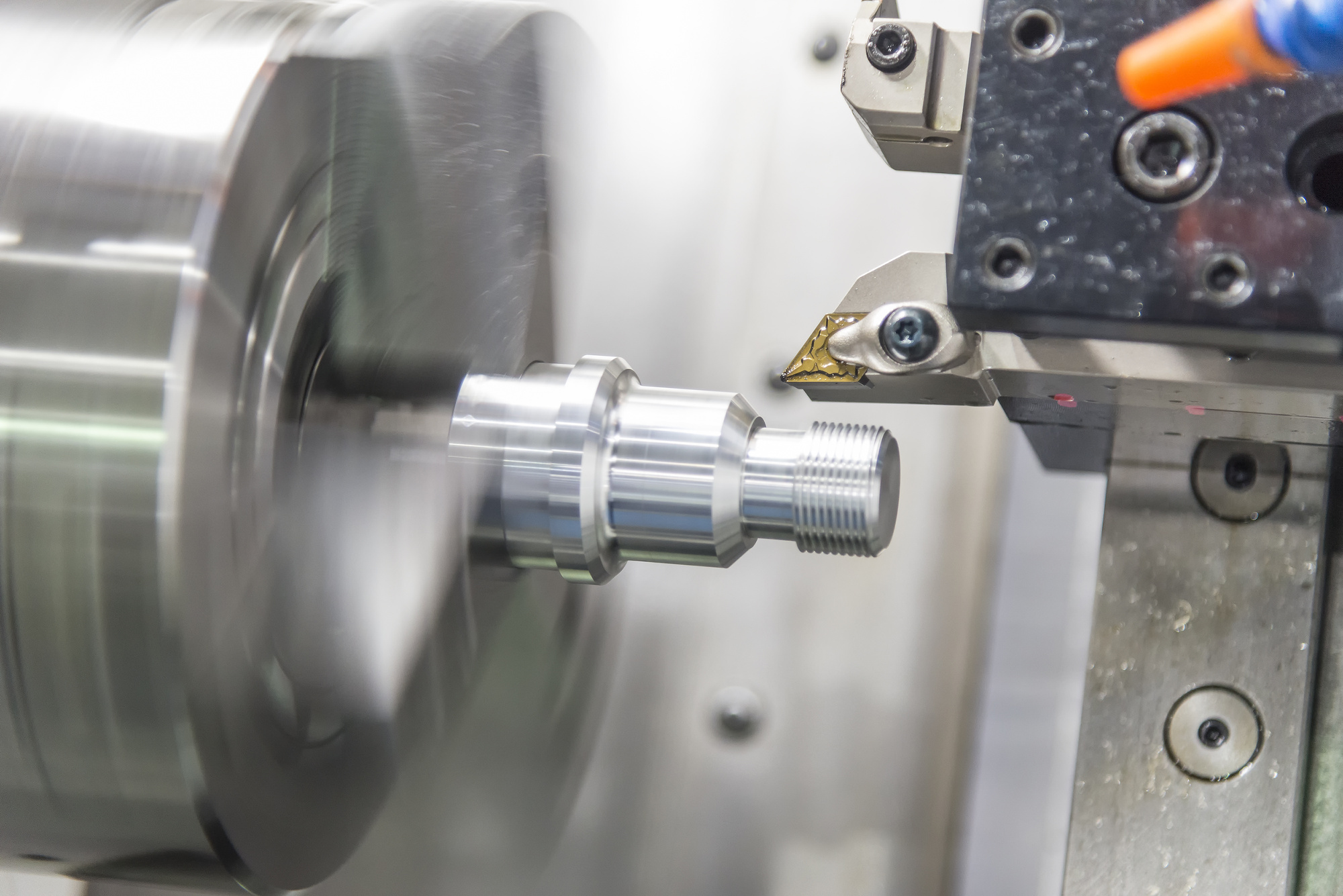

Before exploring its impact on the automotive industry, it’s important to understand what Swiss screw machining is. Swiss screw machining is a type of precision machining that uses a sliding headstock to move the material through a series of tools. The main feature of this process is that the part remains stationary while the tools move around it. This allows for extremely precise cuts, which is critical in industries like automotive manufacturing where precision is key.

Swiss screw machines are capable of producing complex, intricate parts with tight tolerances, which are often required in automotive manufacturing. These machines can handle small, high-precision components that are typically used in engines, transmission systems, and other essential car parts. The ability to produce parts with such high accuracy is one of the reasons why Swiss screw machining has become so important in the automotive sector.

Increased Precision for Critical Automotive Parts

One of the biggest advantages of Swiss screw machining in the automotive industry is the high level of precision it offers. Automotive parts, particularly those that go inside engines and transmissions, require a high degree of accuracy. Even the smallest flaw or miscalculation can lead to serious problems. Swiss screw machining allows for tight tolerances and intricate designs, ensuring that each part fits perfectly and functions as it should.

For instance, parts like fuel injectors, transmission components, and valve guides are all examples of automotive components that require precise machining. Swiss screw machines can produce these components with incredible accuracy, reducing the likelihood of defects and improving the overall quality of the finished product.

Faster Production Times

Another way Swiss screw machining is transforming the automotive industry is by drastically reducing production times. Traditional machining processes can be time-consuming, especially when producing complex components. Swiss screw machines, on the other hand, are designed to handle these tasks more efficiently. The machines can perform multiple operations simultaneously, which speeds up the manufacturing process.

This means that automakers can produce large quantities of parts in a shorter amount of time. In an industry where time is money, this efficiency is invaluable. By cutting down on production times, manufacturers can meet deadlines more easily and keep up with the fast pace of the automotive market.

Cost Savings and Reduced Waste

In addition to saving time, Swiss screw machining also contributes to cost savings for the automotive industry. Since Swiss screw machines are highly efficient, they can produce parts with minimal waste. Traditional machining processes often generate a lot of scrap material, which can drive up production costs. However, Swiss screw machining minimizes waste, which helps manufacturers reduce material costs and improve their bottom line.

Furthermore, the precision of Swiss screw machining means that parts are less likely to be defective. This reduces the need for rework or replacement parts, which can be expensive. The combination of lower waste, fewer defects, and faster production times all contribute to significant cost savings for automotive manufacturers.

Improved Quality and Reliability

In the automotive industry, quality and reliability are non-negotiable. Consumers expect their vehicles to perform flawlessly, and any failure in critical parts can lead to costly recalls and damage to a brand’s reputation. Swiss screw machining plays a vital role in ensuring the high quality and reliability of automotive parts.

Because Swiss screw machines are designed for precision, the parts they produce are less likely to have imperfections. This leads to higher-quality products that perform better and last longer. For automakers, this means fewer returns, fewer warranty claims, and greater customer satisfaction. The ability to produce reliable, high-quality parts is essential for the success of any automotive manufacturer, and Swiss screw machining delivers on this front.

Versatility in Design and Materials

Swiss screw machining is not limited to a single type of material or design. It is highly versatile and can work with a wide range of materials commonly used in the automotive industry, including metals, plastics, and composites. This flexibility allows manufacturers to produce parts for different vehicle systems, including the engine, suspension, and electrical systems.

In addition to being versatile with materials, Swiss screw machining can also handle complex designs. It is particularly useful for producing small, intricate parts that would be difficult or impossible to make using traditional machining methods. This capability opens up new possibilities for automotive engineers to experiment with innovative designs and improve the performance of their vehicles.

Enhancing the Electric Vehicle (EV) Revolution

The rise of electric vehicles (EVs) has created new challenges for the automotive industry, particularly in terms of producing smaller, more intricate components. Swiss screw machining is playing a crucial role in addressing these challenges by providing the precision and speed needed to produce the specialized parts required for EVs.

Electric vehicles require a range of high-precision parts, such as battery components, connectors, and electric motor components. Swiss screw machining is well-suited to produce these parts, ensuring that they meet the necessary standards for performance and reliability. As the demand for EVs continues to grow, Swiss screw machining will become even more integral to the automotive industry’s ability to meet these new requirements.

Supporting Sustainable Manufacturing Practices

Sustainability has become a top priority for many industries, including automotive manufacturing. Swiss screw machining is contributing to more sustainable manufacturing practices by reducing waste, improving efficiency, and minimizing energy consumption. The high precision of Swiss screw machining means that less material is wasted during production, which helps to conserve resources.

Moreover, Swiss screw machines are designed to be energy-efficient, which helps reduce the carbon footprint of the manufacturing process. As automakers face increasing pressure to adopt more sustainable practices, Swiss screw machining offers a solution that aligns with these goals.

Driving Innovation in Automotive Technology

Swiss screw machining is not just improving the way automotive parts are made; it’s also driving innovation in the development of new technologies. As automotive manufacturers strive to improve vehicle performance, safety, and efficiency, Swiss screw machining provides the precision and reliability needed to bring these innovations to life.

From advanced engine components to cutting-edge safety systems, Swiss screw machining is enabling the creation of more complex and efficient automotive technologies. By providing a platform for innovation, Swiss screw machining is helping shape the future of the automotive industry.

Conclusion

Swiss screw machining is undeniably transforming the automotive industry by enhancing precision, reducing production times, and driving cost savings. Its ability to produce high-quality, intricate parts with minimal waste is revolutionizing the way automotive components are made. As the automotive industry continues to evolve, Swiss screw machining will remain a key player in helping manufacturers meet the growing demands for innovation, efficiency, and sustainability.

By improving the quality, reliability, and performance of automotive parts, Swiss screw machining is not only making cars better but also helping automakers stay competitive in a fast-paced industry. Whether it’s the rise of electric vehicles or the constant demand for faster, more efficient manufacturing, Swiss screw machining is paving the way for the next generation of automotive technology.