Fillets and chamfers are fundamental concepts in the world of engineering, design, and manufacturing. These two edge treatments are widely used to improve the functionality, aesthetics, and safety of mechanical parts, products, and structures. Although they share the common goal of modifying sharp edges, they differ significantly in their shapes, applications, and benefits.

This article will explore the differences between Fillet and Chamfer, delve into their individual characteristics, and explain their practical uses in various industries.

What is a Fillet?

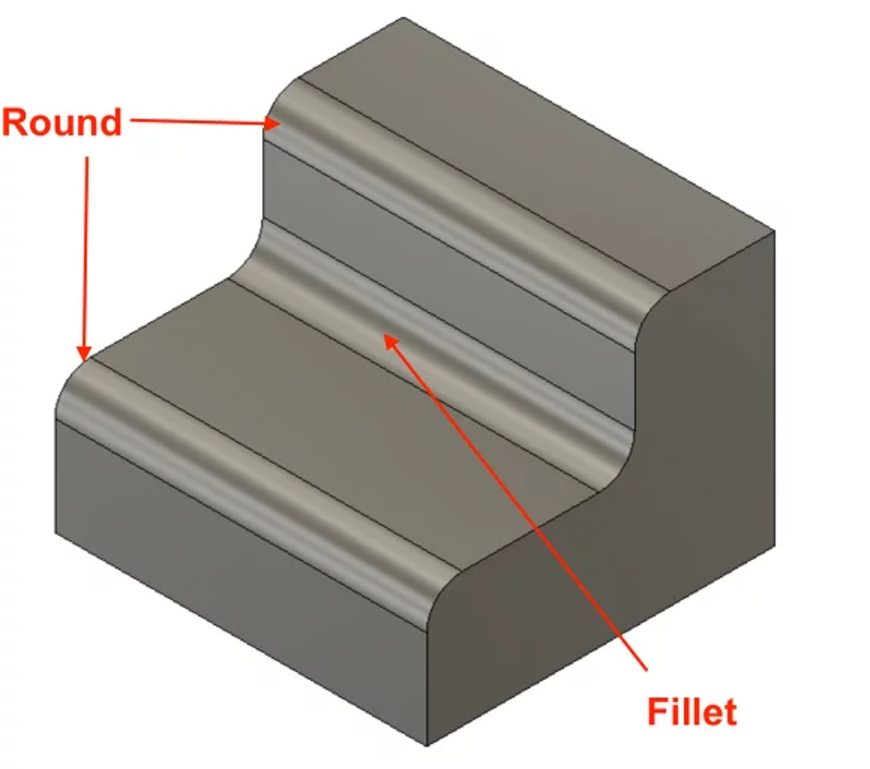

A fillet is a rounded, smooth edge or corner that is used to transition between two surfaces that meet at an angle. Fillets are often applied to internal and external angles to improve strength, distribute stress more evenly, and enhance safety by eliminating sharp corners. A fillet can be found in both 2D and 3D designs and is most commonly used in engineering, architecture, and product design.

Types of Fillets

Fillets can be categorized based on their location and function:

- Internal Fillet: Applied to the inner corner where two surfaces meet at an internal angle. This type of fillet helps in distributing stress and improving the strength of components by reducing points of weakness.

- External Fillet: Applied to the outer corner where two surfaces meet at an external angle. External fillets are often used to improve the aesthetics of a product and to reduce sharp edges that could cause injury or damage.

Applications of Fillets

Fillets serve many important functions across various industries, including:

- Stress Distribution: Fillets help to minimize stress concentration in structural components by creating a smooth transition between parts. In aerospace, automotive, and structural engineering, fillets are used to ensure that stress is evenly spread, reducing the likelihood of cracks and failures.

- Improved Safety: Fillets eliminate sharp edges, which can be dangerous in mechanical parts, tools, or consumer products. For instance, fillets are often used in metal parts, such as brackets or housings, to ensure that edges are not sharp and are safe to handle.

- Cosmetic and Ergonomic Design: Fillets are used to create smooth, rounded corners that are visually appealing and easier to handle. Consumer products such as furniture, electronics, and appliances often feature filleted edges for comfort and aesthetics.

Creating Fillets

Fillets can be created using various methods:

- CNC Machines: Fillets are often machined using Computer Numerical Control (CNC) equipment, which provides high precision and consistency in producing fillets with specific radii.

- Fillet Radius Gauges: To manually check and create fillets, a radius gauge tool can be used to ensure that the curvature matches the design specifications.

What is a Chamfer?

A chamfer refers to the process of beveling or cutting an edge at an angle, usually 45 degrees, to remove the sharpness of a corner. Unlike fillets, which produce a rounded curve, chamfers create straight edges that connect two surfaces at a specific angle. Chamfers are often applied to both internal and external edges and are used to provide a smoother, easier fit for assembly or to improve the product’s appearance.

Types of Chamfers

Chamfers can be categorized into two main types:

- External Chamfer: Applied to the outer corners of a part, this type of chamfer is commonly used in mechanical parts to make them safer to handle and easier to assemble.

- Internal Chamfer: Applied to the inner corners of a part, internal chamfers are used to improve assembly by facilitating the fitting of parts together.

Applications of Chamfers

Chamfers serve a range of purposes in engineering and design, such as:

- Assembly Facilitation: Chamfers make it easier to assemble parts by allowing them to fit together more precisely. For example, in mechanical components, a chamfered edge allows for smooth insertion into mating parts, especially in complex assemblies like engines or machinery.

- Safety and Handling: Like fillets, chamfers are used to remove sharp edges from parts, making them safer to handle during manufacturing and assembly processes. This is particularly important in metalworking and plastic parts, where sharp edges can lead to injuries or tool damage.

- Aesthetic Enhancement: Chamfers are also applied to improve the appearance of a product. By creating clean, angled edges, chamfers can give parts a more polished and refined look, which is especially important in consumer goods such as electronics and furniture.

Creating Chamfers

Chamfers can be produced using various tools and techniques:

- CNC Milling: In modern manufacturing, CNC milling machines are often used to create precise chamfers on both internal and external edges.

- Hand Tools: Chamfers can also be applied manually using files, chamfering tools, or saw blades for simpler projects or small-scale manufacturing.

Key Differences Between Fillet and Chamfer

While both fillets and chamfers are used to modify the edges of a part, they differ significantly in their shapes, purposes, and applications. Here’s a comparison of the two:

| Feature | Fillet | Chamfer |

|---|---|---|

| Shape | Rounded, curved edge | Angled, straight edge |

| Location | Typically applied to internal or external edges | Typically applied to external or internal edges |

| Function | Reduces stress, enhances strength, improves safety | Eases assembly, improves appearance, removes sharp edges |

| Application | Structural parts, aesthetic designs, ergonomic products | Assembly components, machine parts, decorative finishes |

| Common Angle | Radius (curved) | 45 degrees (though other angles can be used) |

Stress Distribution vs. Ease of Assembly

- Fillets are typically used when reducing stress concentrations is critical. By rounding off sharp internal corners, fillets help to distribute forces evenly and prevent failure points in structural or high-stress components.

- Chamfers, on the other hand, are often used to facilitate assembly and to improve part fitment. A chamfered edge makes it easier for parts to fit together smoothly, reducing the risk of damage or difficulty during the assembly process.

Aesthetics and Handling

While both fillets and chamfers can improve the appearance of a part by softening harsh edges, fillets tend to provide a more organic, flowing look, while chamfers offer a cleaner, more defined, and angular appearance. Additionally, both are used to make parts safer to handle. However, fillets are better suited for ergonomic designs where smoothness is important, while chamfers are ideal for parts that require an easy fit or alignment.

Choosing Between Fillets and Chamfers

The decision to use a fillet or chamfer depends on several factors, such as the function of the part, the material being used, and the design requirements. Here are some considerations for making the right choice:

- Fillet: Choose a fillet when you need to reduce stress concentrations or improve the structural integrity of the part. Fillets are also preferred when a smooth, rounded edge is required for safety, comfort, or aesthetic appeal.

- Chamfer: A chamfer is the better choice when ease of assembly is crucial, especially when parts need to fit together precisely. Chamfers are also the preferred option when an angular or beveled edge is required for visual appeal or when a sharp corner needs to be safely removed.

Common Applications of Fillets and Chamfers in Industries

Fillets and chamfers are used extensively across various industries:

- Automotive Industry: Both fillets and chamfers are used in the manufacturing of automotive components such as engine parts, frames, and body panels. Fillets help reduce stress on parts, while chamfers improve assembly and safety.

- Aerospace Engineering: In aerospace, fillets are crucial for reducing stress and ensuring the structural integrity of components like wings and fuselage parts, while chamfers help with the precise fitting of mechanical parts.

- Consumer Electronics: Fillets and chamfers are often used in product design for electronics, providing both functional benefits (e.g., easier assembly and enhanced strength) and aesthetic improvements (e.g., smoother, more visually appealing edges).

- Construction and Architecture: In construction, fillets and chamfers are used in metal structures, concrete elements, and furniture. Fillets are applied to reduce the risk of cracks in structural parts, while chamfers are used for safety, aesthetics, and ease of construction.

Conclusion

Fillets and chamfers are indispensable tools for engineers, designers, and manufacturers, each serving distinct but equally important roles. Fillets provide smooth, rounded transitions that reduce stress concentrations and enhance the safety and integrity of parts, while chamfers offer angular edge modifications that ease assembly, improve fitment, and contribute to aesthetic designs. Whether working in aerospace, automotive, architecture, or consumer product design, understanding when and how to use fillets and chamfers can dramatically improve both the functionality and appearance of a product.