Custom machinery design plays a crucial role in enhancing operational flexibility across various industries. For a Lab Equipment Supplier in New York, tailoring machinery to specific operational needs allows businesses to adapt quickly to changing requirements, improve efficiency, and stay competitive. This article explores how custom machinery design contributes to operational flexibility, focusing on adaptability, efficiency, and scalability. By customizing equipment, a Lab Equipment Supplier in New York can offer solutions that meet precise needs, enabling faster responses to industry changes and improved overall performance.

Adapting to Unique Operational Needs

Tailoring to Specific Applications

Meeting Unique Requirements

Custom machinery is designed to meet the specific needs of a business or industry, accommodating unique processes, products, or production methods. By focusing on precise requirements, custom machinery ensures that operations are optimized for efficiency and effectiveness, enhancing overall flexibility.

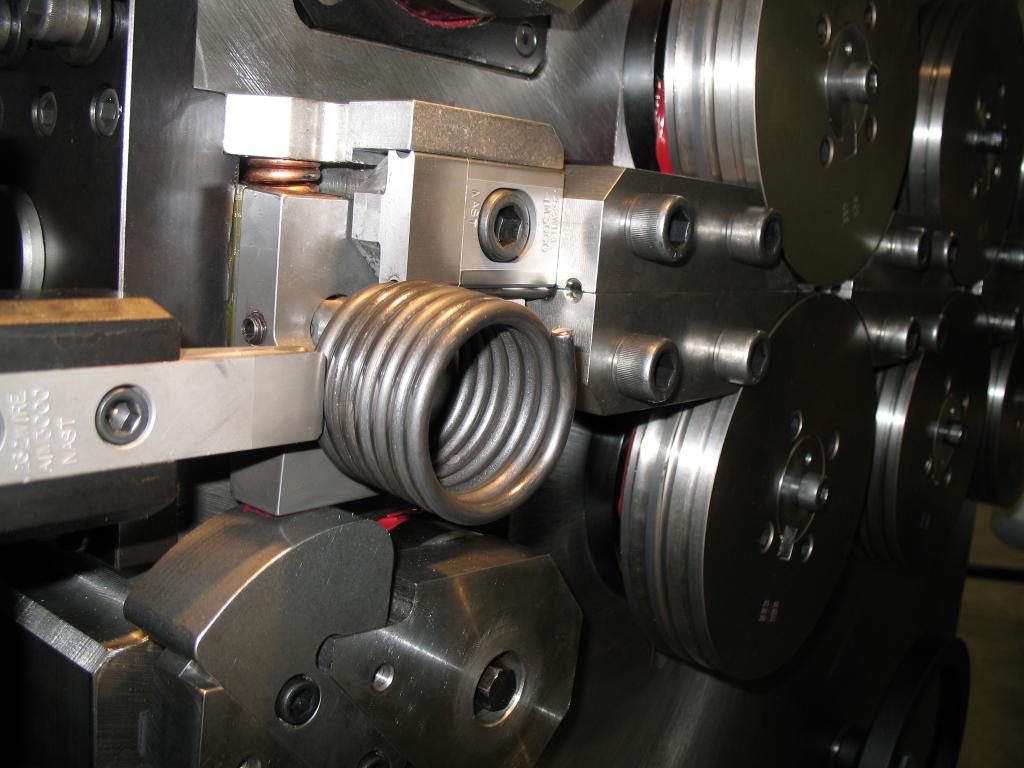

Incorporating Specialized Features

Custom machinery can be equipped with specialized features that address particular challenges or requirements. This might include adjustable components, configurable settings, or integrated systems that allow the machinery to handle diverse tasks and processes.

Enhancing Versatility

Modular Design Approaches

Modular design involves creating machinery with interchangeable components or modules that can be easily reconfigured or replaced. This approach allows businesses to adapt the machinery for different functions or processes without the need for a complete redesign, providing significant operational flexibility.

Adjustable Settings and Parameters

Custom machinery can be designed with adjustable settings and parameters that allow operators to modify the equipment’s functionality based on varying production needs. This adaptability ensures that the machinery can quickly switch between different tasks or products, enhancing flexibility.

Improving Efficiency and Productivity

Streamlining Operations

Optimizing Workflow Integration

Custom machinery is designed to integrate seamlessly with existing workflows and systems, reducing bottlenecks and inefficiencies. By aligning machinery design with operational processes, businesses can streamline production and improve overall efficiency, contributing to greater flexibility.

Minimizing Downtime

Custom machinery can be designed with features that minimize downtime, such as quick-change mechanisms, automated diagnostics, and efficient maintenance procedures. Reducing downtime enhances operational flexibility by ensuring that production processes remain uninterrupted and responsive to changing demands.

Enhancing Automation and Control

Implementing Advanced Technologies

Incorporating advanced technologies, such as automation, robotics, and data analytics, into custom machinery can significantly enhance efficiency. These technologies enable precise control, real-time monitoring, and data-driven decision-making, allowing businesses to adapt quickly to changing conditions and optimize performance.

Facilitating Remote Operation

Custom machinery can be equipped with remote operation capabilities, enabling operators to control and monitor the equipment from a distance. This flexibility allows for quicker adjustments, troubleshooting, and management, even when physical access to the machinery is limited.

Supporting Scalability and Growth

Accommodating Increased Production Demands

Designing for Scalability

Custom machinery can be designed with scalability in mind, allowing it to accommodate increased production demands without requiring a complete overhaul. Features such as modular components, expandable capacity, and adaptable configurations support growth and enable businesses to scale their operations efficiently.

Ensuring Long-Term Flexibility

Investing in custom machinery that supports scalability ensures long-term flexibility. As production needs evolve or new products are introduced, businesses can adapt their machinery to meet changing requirements, avoiding the need for frequent replacements or upgrades.

Facilitating Product Innovation

Supporting New Product Development

Custom machinery can be designed to support the development and production of new products. Features such as interchangeable tools, adjustable settings, and versatile processing capabilities allow businesses to experiment with new designs and materials, fostering innovation and maintaining competitive advantage.

Adapting to Market Trends

Custom machinery can be modified to respond to market trends and shifting consumer preferences. By incorporating adaptable design elements and flexible functionality, businesses can quickly adjust their production processes to align with changing market demands and opportunities.

Enhancing Operational Safety and Compliance

Integrating Safety Features

Customizing Safety Measures

Custom machinery can be designed with integrated safety features that address specific risks associated with particular operations or environments. This might include safety guards, emergency stop systems, and advanced sensors that enhance operator protection and compliance with safety regulations.

Adapting to Regulatory Changes

Custom machinery can be modified to comply with evolving industry standards and regulations. By incorporating design elements that address current safety and compliance requirements, businesses can ensure that their operations remain up-to-date and aligned with regulatory expectations.

Supporting Safe and Efficient Maintenance

Designing for Easy Maintenance

Custom machinery can be designed to facilitate easy maintenance, with features such as accessible service points, modular components, and automated diagnostics. This design approach helps maintain operational flexibility by ensuring that the machinery remains in optimal condition with minimal downtime.

Providing Comprehensive Documentation

Providing detailed documentation and support resources for custom machinery enhances maintenance and operational flexibility. Comprehensive guides, training materials, and technical support ensure that operators can effectively manage and troubleshoot the machinery, maintaining smooth and efficient operations.

Conclusion

Custom machinery design significantly enhances operational flexibility by tailoring equipment to specific needs, improving efficiency, supporting scalability, and integrating advanced technologies. By focusing on adaptability, automation, and safety, custom machinery enables businesses to respond swiftly to changing demands, optimize production processes, and sustain long-term growth. Investing in custom machinery that aligns with operational requirements and supports flexibility ensures a competitive edge and drives success in a dynamic marketplace.