316 stainless steel is a popular grade of stainless steel that is widely used in various industries due to its exceptional properties. Known for its excellent corrosion resistance, high strength, and good machinability, 316 stainless steel is a versatile material suitable for a range of applications. In this blog, we will delve into the key properties of 316 stainless steel, exploring what makes it an ideal choice for demanding environments.

Chemical Composition

316 stainless steel is an austenitic stainless steel, primarily composed of iron, chromium, nickel, and molybdenum. The typical chemical composition of 316 stainless steel includes:

- Chromium: 16-18%

- Nickel: 10-14%

- Molybdenum: 2-3%

- Iron: Balance

- Other Elements: Trace amounts of carbon, manganese, silicon, phosphorus, and sulfur

The addition of molybdenum enhances its corrosion resistance, particularly against chlorides and other industrial solvents.

Corrosion Resistance

One of the standout properties of 316 stainless steel is its superior corrosion resistance. The presence of molybdenum provides enhanced protection against pitting and crevice corrosion in chloride environments, making it ideal for use in marine and coastal applications. Additionally, 316 stainless steel offers excellent resistance to acidic and alkaline solutions, making it suitable for chemical processing and pharmaceutical industries.

Mechanical Properties

316 stainless steel exhibits impressive mechanical properties, which contribute to its versatility and durability:

- Tensile Strength: Approximately 579 MPa (84 ksi)

- Yield Strength: Approximately 290 MPa (42 ksi)

- Elongation: 40% in 50 mm

- Hardness: Brinell hardness of 217 HB

These mechanical properties ensure that 316 stainless steel can withstand high-stress environments and maintain its structural integrity under heavy loads.

Heat Resistance

316 stainless steel also offers good heat resistance, retaining its strength and stability at high temperatures. It can withstand continuous exposure to temperatures up to 870°C (1598°F) and intermittent exposure up to 925°C (1697°F). This property makes it suitable for applications involving high heat, such as furnace parts, heat exchangers, and jet engine components.

Weldability and Fabrication

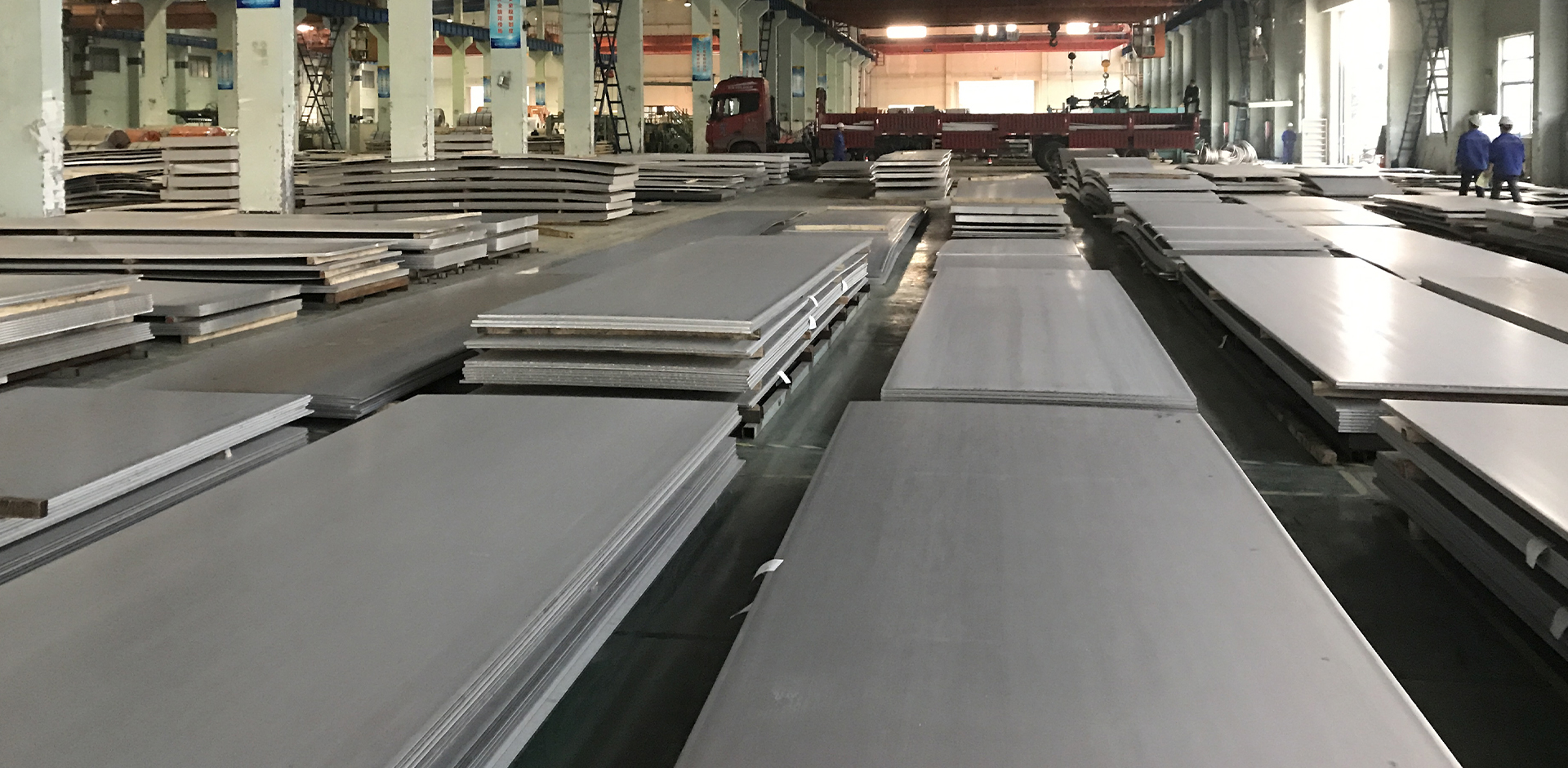

316 stainless steel is known for its excellent weldability and ease of fabrication. It can be readily welded using standard welding techniques, such as TIG, MIG, and resistance welding. Its machinability is also commendable, allowing for the efficient production of complex shapes and components. This makes it a preferred material for manufacturing 316 Stainless Steel plates and other industrial products.

Hygienic Properties

Another significant advantage of 316 stainless steel is its hygienic properties. It is non-reactive and non-toxic, making it an ideal material for use in food processing, medical, and pharmaceutical applications. Its smooth surface is easy to clean and sterilize, ensuring high levels of hygiene and reducing the risk of contamination.

Applications

The versatile properties of 316 stainless steel make it suitable for a wide range of applications, including:

- Marine and Coastal Environments: For shipbuilding, offshore platforms, and coastal structures.

- Chemical Processing: In chemical tanks, heat exchangers, and pipelines.

- Food and Beverage Industry: For food processing equipment, brewing tanks, and dairy machinery.

- Medical and Pharmaceutical: In surgical instruments, pharmaceutical equipment, and implantable devices.

- Oil and Gas Industry: For pipeline systems, valves, and pumps exposed to corrosive environments.

Conclusion

316 stainless steel is a highly versatile material with exceptional properties that make it suitable for various demanding applications. Its superior corrosion resistance, impressive mechanical properties, and excellent weldability make it an ideal choice for industries ranging from marine and chemical processing to food and medical applications. Understanding these properties helps in selecting the right material for specific applications, ensuring durability, safety, and cost-effectiveness. By choosing high-quality 316 Stainless Steel plates, industries can leverage these benefits to enhance their operations and maintain the integrity of their equipment in challenging environments. Whether it’s for structural components in harsh marine environments or hygienic applications in food processing, 316 stainless steel stands out as a reliable and efficient material choice.